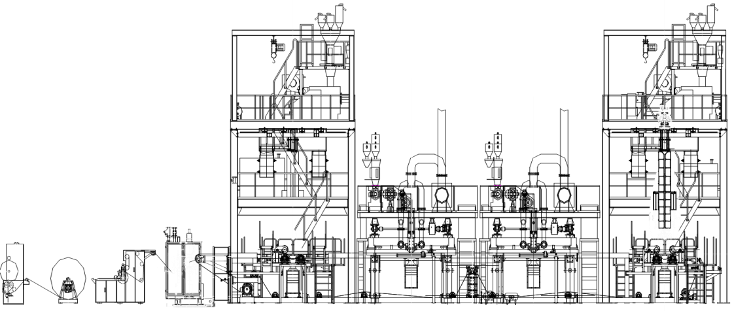

POWER-FRAME SFP-4 Nonwovens

The BR�CKNER stenter is always used when the nonwovens should have a defined width after the heat treatment process. In addition to a purely width-controlled operation, the lateral forces within the web can also be detected. These values can then be alternatively taken as basis parameter for the wid

Here you will find your personal contact.

Please choose your country.